DEPOSITION TECHNOLOGY FOR PVD AND PACVD

TiN

The general-purpose coatingUse:

Low carbonsteel cutting, moulds for the injection molding of plastics, rubber, decorative coating.

Specification:

| coating color: | gold |

| max. service temperature: | 600 °C |

| coating hardness: | 24 GPa (2400 HV) |

| friction coeficient: | 0,55 |

TiCN

Coasting with high protection against abraseive wear.Use:

Milling, tapping, thread forming of steel.

Specification:

| coating colo: | gray |

| max. service temperature: | 400 °C |

| coating hardness: | 35 GPa (3500 HV) |

| friction coeficient: | 0,2 |

TiCN MP

Gradient multipurpouse coating with low-friction coefficientUse:

Interrupted cutting, milling and tapping of mild strength steel.

Specification:

| color: | bronzebrown |

| max. service temperature: | 400 °C |

| coating hardness: | 32 GPa (3200 HV) |

| friction coeficient: | 0,2 |

ZrN

Coating with good resistance against built up edge when machining aluminium and titanium alloysUse:

Cutting, forming, stamping of aluminium and titanium alloys

Specification:

| color: | white-gold |

| max. service temperature: | 550 °C |

| coating hardness: | 20 GPa (2000 HV) |

| friction coeficient: | 0,4 |

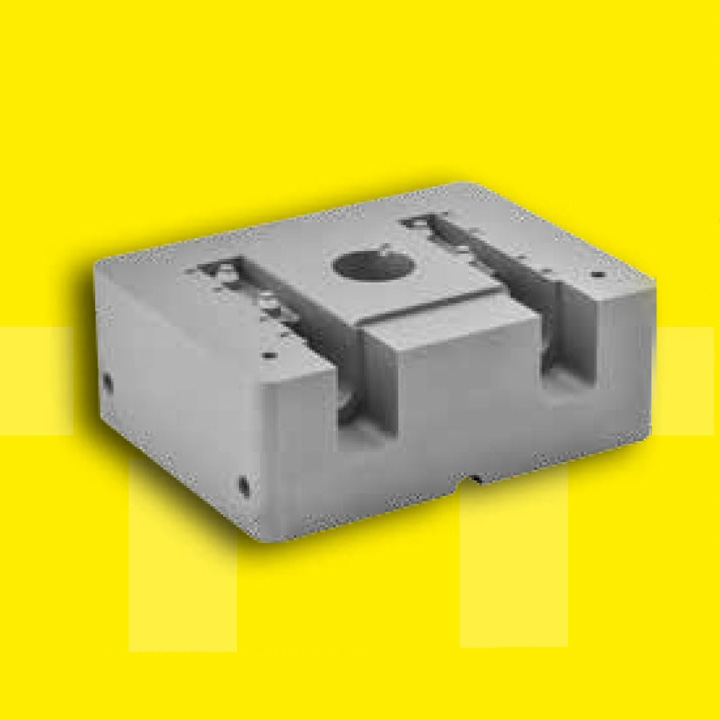

CrN

Coating with very good wear resistence, Protects against galling.Use:

Machining of cooper and other soft materials, injection moulding, machine parts.

Specification:

| color: | metallic silver |

| max. service temperature: | 700 °C |

| coat hardness: | 18 GPa (1800 HV) |

| friction coeficient: | 0,3 |

TiAICN

High performed coating for low friction coaficient and higher oxidation resistance.Use:

Milling, drilling and of alloyed steel, forming, stamping and drawing of steel.

Specification:

| color: | bronze violet |

| max. service temperature: | 500 °C |

| coating hardness: | 30 GPa (3300 HV) |

| friction coeficient: | 0,3 |

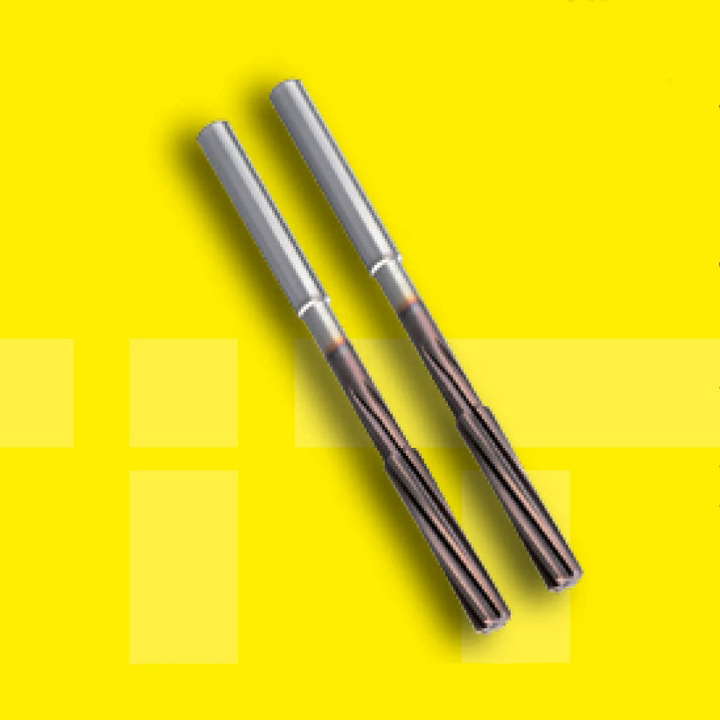

TiAIN

Universal hogh-performance coating for productive cutting.Use:

Mlling, drilling, reaming

Specification:

| color: | purple black |

| max. service temperature: |

700 °C |

| coating hardness: | 28 GPa (2800 HV) |

| friction coeficient: | 0,6 |

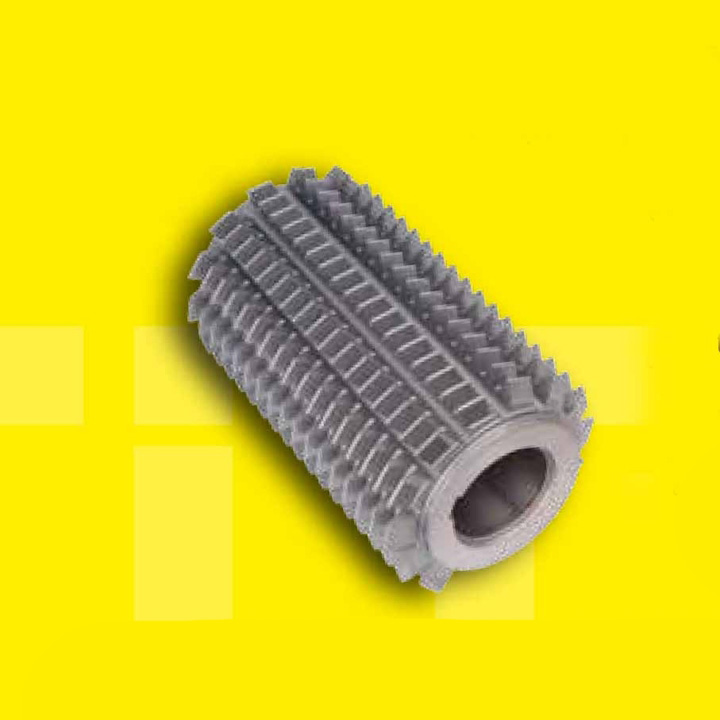

AITiN

High performance multilayer coating for use in hard and high speed machining.Use:

Drilling, milling, gear cutting.

Specification:

| color: | black |

| max. service temperature: | 850 °C |

| coating hardness: | 33 GPa (3300 HV) |

| friction coeficient: | 0,7 |

AITiN G

High performance gradient coating with high wear resistance.Use:

Drilling, injection molds for plastic with abrasive fillers or high glass fiber content.

Specification:

| color: | black |

| max. service temperature: |

900 °C |

| coating hardness: | 38 GPa (3800 HV) |

| friction coeficient: | 0,7 |

nACo®

Nanocomposite PLATIT coating with extremely high hardness and extreme high heat resistance.Use:

For hard machining milling, dry turning, reaming, dry cutting, HSC cutting.

Specification:

| color: | violet blue |

| max. service temperature: | 1200 °C |

| coating hardness: | 45 GPa (4500 HV) |

| friction coeficient: | 0,45 |

nACRo®

Nanocomposite PLATIT coating with high resistance against abrasive wear and with high heat resistance.Use:

Machining of difficult to cut materials, high alloyed materials, titanium.

Specification:

| color: | blue gray |

| max. service temperature: | 1100 °C |

| coating hardness: | 40 GPa (4000 HV) |

| friction coeficient: | 0,35 |

nACo4®

Nanocomposite coating of the 4th generationUse:

Improved flexibility for drilling, milling alloyed steel.

Specification:

| color: | dark blue |

| max. service temperature: | 1200 °C |

| coating hardness: | 41 GPa (4100 HV) |

| friciton coefficient: | 0,4 |

nACRo4®

Nanocomposite coating of the 4th generation.Use:

Cutting abrasive materials, dry machining with higher Cr content.

Specification:

| color: | gray-black-yellow |

| max. service temperature: | 1100 °C |

| coating hardness: | 40 GPa (4000 HV) |

| friction coefficient: | 0,35 |

FeinAL®

Dedicated multifunctional coating for fine blanking developed with Feintool A.G.Use:

Tools for blanking and fine blanking.

Specification:

| color: | grey |

| max. service temperature: | 1000 °C |

| coating hardness: | 35 GPa (3500 HV) |

| friction coefficient: | 0,6 |

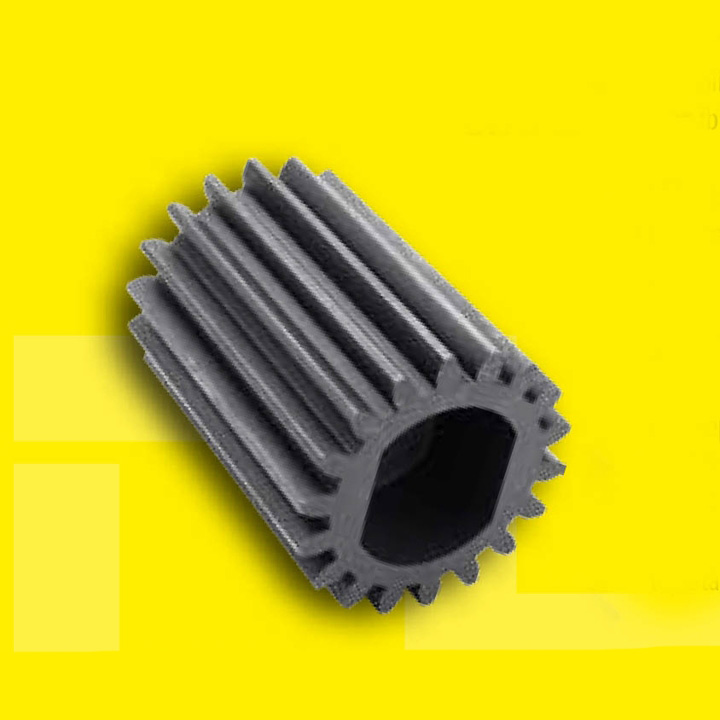

AIXN3

Nanolayred coating with high wear resistance and hot hardness.Use:

Gear cutting, punching, stamping, blanking, cutting of high strength steel

Technické parametry:

| color: | grey-black |

| max. service temperature: | 900 °C |

| coating hardness: | 32 GPa (3200 HV) |

| friction coefficient: |

0,4 |

Duplex TiCN

Special technology – combination of plasma nitriding and PVD coating.Use:

High performance coating for forming and punching of high strength steel.

Specification:

| color: | gray |

| max. service temperature: | 400 °C |

| coating hardness: | 37 GPa (3700 HV) |

| friction coefficient |

0,2 |

TiN-SCiL®

High performance coating for cutting of soft materials.Use:

Very low coating roughness for drilling, milling and tapping.

Specification:

| color: | gold |

| max. service temperature: | 600 °C |

| coating hardness: | 26 GPa (2600 HV) |

| friction coefficient: |

0,35 |

TiB2-SCiL

The high-performance sputtered coating for avoid built up edges at cutting sticky materials.Use:

Cutting of non-ferrous material like aluminium, cooper and plastic.

Specification:

| color: | light gray |

| max. service temperature: | 600 °C |

| coating hardness: | 30 GPa (3000 HV) |

| friciton coefficient: | 0,35 |

MOVIC®

Dry lubricant coatings with extremlly low friction coaficient.Use:

Dry lubrication, tappig, forming.

Specification:

| color: | black |

| max. service temperature: | 400 °C |

| coating hardness: | – |

| friction coefficient: | 0,1 |

DLC

Low friction carbon base coating.Use:

Precision components and tools.

Specification:

| color: | black |

| max. service temperature: | 400 °C |

| coating hardness: | 25 GPa (2500 HW) |

| friction coefficient: | 0,15 |